Flexibility

SOLUTIONS FOR RAILWAY TRANSPORTATION

Proactive dynamism and streamlined production processes allow Margaritelli Ferroviaria to stay abreast of technological innovation in the railway construction industry and design the best solutions to meet new industry requirements. Our extensive product range, sleeper customisation, high quality production engineering, short lead times and logistic competence make Margaritelli a truly flexible company.

Proactive dynamism and streamlined production processes allow Margaritelli Ferroviaria to stay abreast of technological innovation in the railway construction industry and design the best solutions to meet new industry requirements. Our extensive product range, sleeper customisation, high quality production engineering, short lead times and logistic competence make Margaritelli a truly flexible company.

Logistics

-

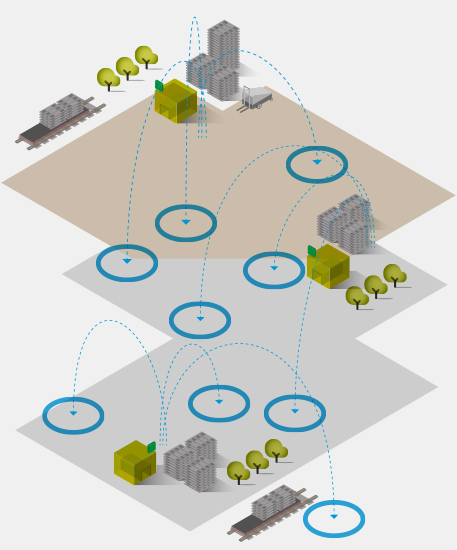

Logistics managed by rail

In the modern day railway construction industry logistics are of strategic importance and can make all the difference, optimal use must be made of the most suitable transport solutions. Margaritelli Ferroviaria is structured with this in mind, optimising the opportunities to transport goods by rail, the most sustainable option in both economic and environmental terms.

-

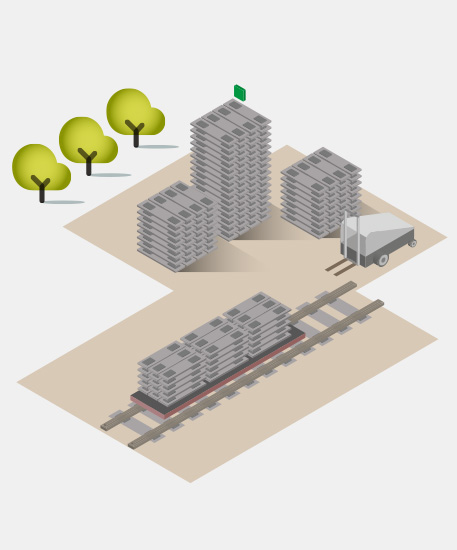

Storage facilities

To guarantee a constant flow of provisioning and facilitate track laying when supplying sleepers for new railway line construction projects, Margaritelli Ferroviaria specialises in designing and setting up temporary storage facilities making sleepers easily accessible from railway construction sites, taking on the operational management of these facilities and providing the necessary machinery and manpower.

-

Reliable service

The geographical distribution of our production capacity, optimisation of the most suitable combinations of transport options along with flexible and efficient logistic solutions are all key factors of our ability to offer a highly reliable service in terms of meeting delivery terms on schedule.

Quality

The search for quality, in all our activities, has always been a driving factor at Margaritelli Ferroviaria. With the aim of reinforcing our reliability in an approach of continuous improvement, we operate with a Quality management system ISO9001 certified

The search for quality, in all our activities, has always been a driving factor at Margaritelli Ferroviaria. With the aim of reinforcing our reliability in an approach of continuous improvement, we operate with a Quality management system ISO9001 certified